Furnace Systems

Press hardening of steel and hot forming of high-strength aluminum

AP&T's furnace systems for press hardening of steel and hot forming of high-strength aluminum meet high demands for cycle times, repeatability, flexibility, availability, shop floor utilization and energy performance.

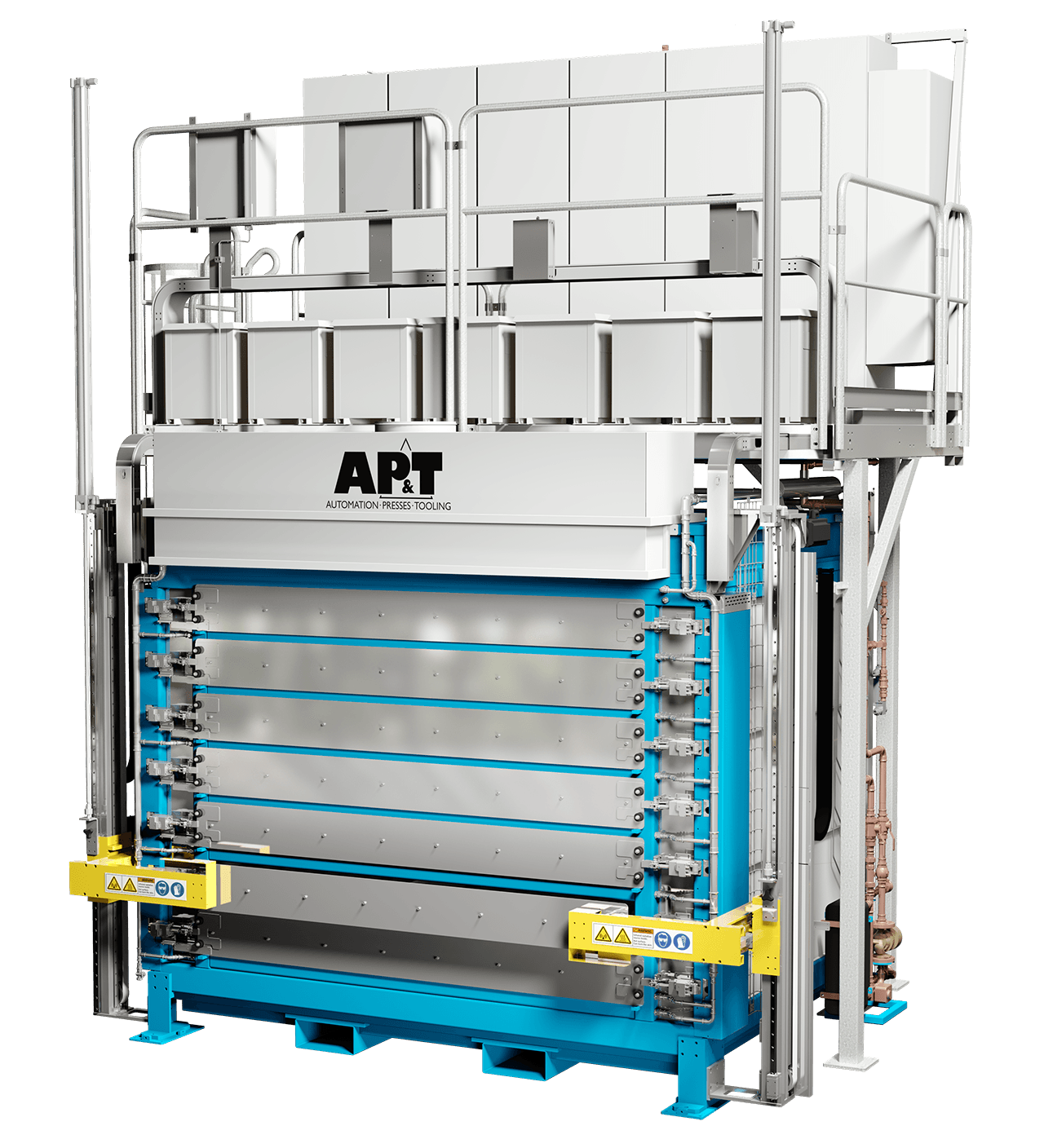

Multi-Layer Furnace system

With our unique Multi-Layer Furnace system, we offer a fully automated, compact, electric, energy-efficient solution with only a few moving parts and a minimum need of maintenance. The design, with multi-layer single chambers, also makes production significantly less sensitive to operational disturbances than conventional alternatives.

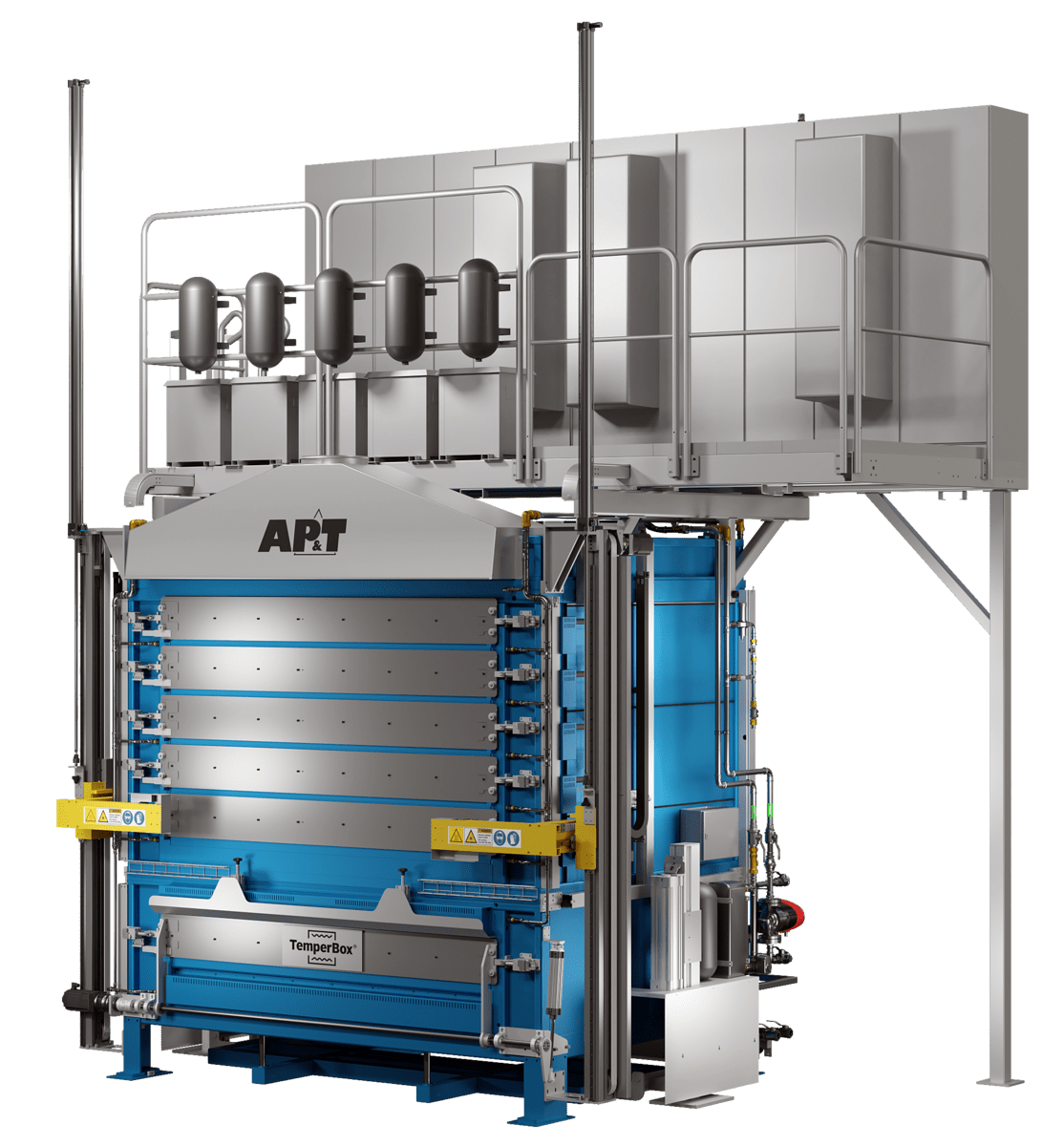

TemperBox® – propelling press hardening into the future

The Multi-Layer Furnace comes equipped with an advanced system for process monitoring, which makes it possible to meet specific quality demands. Our patented TemperBox® enables production of components with a tailored combination of hard and soft zones, without compromising cycle times. It integrates well with the Multi-Layer Furnace but can also be added to any other state-of-the-art furnace types. TemperBox® runs on electricity.

Hot forming of high-strength aluminum

With our lines for hot forming of high-strength aluminum we also offer Multi-Layer Furnaces with Jet Heating technology, which features high performance and precision heat treatment in a very compact format.

The system can either be run on electricity or gas.